Solar Van Man's RV Solar Design Process: How We Engineer Enduring RV Energy Systems

At Solar Van Man, we don’t install “solar kits.” We design bespoke RV microgrid energy systems tailored to your camping style. What kind of RVer are you? Do you "Sit and Sip" or Run and Gun"? Lifestyles dictate electrical behavior. That’s why our process is structured, deliberate, and repeatable. Our deliberate study of how you use energy when you camp is how we ensure your RV energy systems work on day one and on day 4,380, because depending on which RV lithium batteries you order from Solar Van Man, that's how long your LiFEPo4 batteries could be under warranty.

Step 1: Electrical Survey & Load Discovery

We begin by educating you on how much power your RV uses with your camping style.

This includes:

Existing inverter, converter, and transfer switch configuration

Battery type, capacity, and mounting location

AC and DC load inventory (current and future)

Generator integration (if present)

Roof space and structural considerations

For many customers, this is the first time their RV’s electrical system has been evaluated as a whole. Every RV solar and battery electrical system has different constraints: roof space, alternator capacity, inverter loads, battery bay volume, and camping styles. Solar Van Man follows a structured, engineering-first process to design RV energy systems that are safe, serviceable, and matched to real-world usage.

Every project starts with understanding how the RV is used.

We review:

- RV type (Class A, B, C, fifth wheel, travel trailer)

- Existing electrical system (inverter, converter, batteries, wiring)

- Typical loads (air conditioning, cooking, medical equipment, office gear)

- Travel style (boondocking, campground, full-time, seasonal)

- Charging sources (shore power, generator, alternator)

This step prevents over- or undersizing and avoids expensive redesigns later.

All work is performed by appointment and tailored to the specific RV and owner requirements.

Outcome: A clear picture of real-world electrical demand — not assumptions.

Step 2: Electrical Audit & Feasibility Check

We perform a practical electrical audit of the RV, which may include:

- DC and AC distribution layout

- Battery compartment dimensions and ventilation

- Roof layout and usable solar area

- Alternator output and engine charging capability

- Existing safety devices and grounding

If limitations exist (space, weight, alternator capacity), they are identified early and factored into the design.

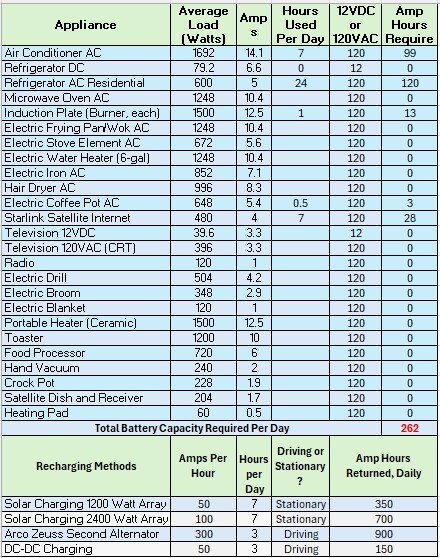

Step 3: System Architecture & Load Calculations

Based on the audit, we design a complete RV energy system architecture, including:

- Inverter/charger sizing (2 kW, 3 kW, 5 kW, 10 kW, etc…)

- Battery chemistry and capacity (e.g.: LiFePO₄ 360Ah)

- Solar array configuration and MPPT sizing

- DC-DC or second-alternator charging

- Shore and generator integration

- Protection devices (fusing, disconnects, monitoring)

Load calculations are based on actual usage, not marketing assumptions.

Step 4: Component Selection & Compatibility Review

Components are selected based on:

- Electrical compatibility

- Thermal and mechanical constraints

- Serviceability

- Manufacturer support

- Long-term reliability

Solar Van Man specifies only proven RV-grade components rather than consumer solar equipment adapted for mobile use.

Step 5: Installation Planning

Before RV energy component installation, we plan:

- Cable routing and penetration points

- Roof mounting locations of panels

- Battery mounting and restraint

- Components attached and wired to backer board and bench tested

- Ventilation and heat management

- Access for future service

- Compliance with NFPA 1192

This step ensures the installation is clean, safe, and maintainable.

NFPA 1192, the Standard on Recreational Vehicles, provides essential fire, life, and safety criteria for RVs, covering requirements for plumbing, fuel systems, electrical installations, fire/CO detection, means of egress, and vehicular safety. Published by the National Fire Protection Association, it ensures minimum safety standards for manufacturing, with updates occurring on a three-year cycle, impacting manufacturers and builders of motorhomes, campers, and other recreational vehicles to protect occupants and property.

Step 6: Installation & Integration

Installation includes:

- Mechanical mounting of solar panels, wires, inverter, DC-DC charging/second alternator, MPPT Controller, cooling fan(s), Lynx Distributor/Busbars, Cerbo GX + Touch 50.

- Proper conductor wire is sized per load, and the components are mounted to the backer board and bench tested.

- Correct over-current protection installed and proper fusing/circuit breakers, especially between panels and the MPPT.

- Clean system labeling is installed

- Integration with existing RV 12V and 120V electrical systems

All work is performed using RV-appropriate materials and techniques.

Step 7: Testing, Commissioning & Handover

After installation:

- All charging sources are tested

- Inverter and battery parameters are configured

- Monitoring systems are verified

- Safety checks are completed

The owner is walked through system operation, limitations, and basic troubleshooting.